Traditional print manufacturing processes are structured to balance the tradeoff between run counts and the number of jobs/makereadies. In the bindery, higher net book production has been realized using faster machines being fed longer print runs with fewer makereadies. However, today’s trend towards high output, shorter print runs has completely upended this paradigm.

Market demand for flexible manufacturing is obsoleting legacy binding equipment.

The productivity of high-speed binding lines has been hobbled by new market requirements to schedule short runs of arbitrary sizes and formats. Plus, the digital presses’ ability to print in sequence is obsoleting the need for gathering machines that not only take up space, but consume the majority of makeready time. These dynamics accelerate the need for new finishing equipment and manufacturing processes, as do increases in digital printing quality, throughput, personalization and market demand. Yet, throughout, the demand for faster turnaround, lower unit cost and less labor remains constant.

Your future in finishing is available today.

For many years, Muller Martini has been the market leader in finishing automation and touchless workflow, reducing labor for material handling, lessening makeready with servo drive technology, and transferring job data to and from production lines with industry standard JDF and JMF protocols. (In fact, Muller Martini is a charter member of the CIP3 consortium which develops and maintains the entire JDF/JMF standard for the print industry.)

Muller Martini introduced the first automated saddle stitcher and perfect binder with motorized makeready and adjustment features. And, at drupa 2002, it displayed the first saddle stitcher and perfect binder directly integrated into a digital web. These forward-thinking developments to better manage productivity, throughput, and connectivity in the bindery formed the basis of our Finishing 4.0 engineering and design philosophy.

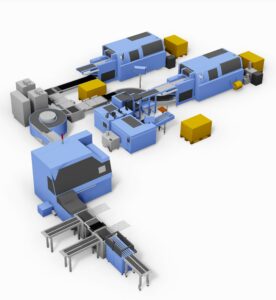

Today, the latest Finishing 4.0 production concept builds on the success of two key additions to the digital short-run book space: the fully automated Vareo perfect binder and the InfiniTrim three-knife trimmer. The Vareo is seeing wide adoption in digital book markets because of its high productivity in book-of-one and book-of-few applications. And, the addition of the all-new variable thickness integrated endsheet tipper and crash feeder further extend this capability into short-run hardcover production. The InfiniTrim is unlike any three-knife trimmer ever produced. It is, in fact, an industrial robot capable of trimming streams of books of arbitrary size or thickness with no operator intervention or slowdown. Used together, the Vareo and InfiniTrim achieve the highest throughput and highest flexibility in book production today.

…and tomorrow.

Of particular importance to printing companies is the ability to scale this production concept over time to keep pace with the growth of digital print processes in their particular operations. As digital presses contribute higher numbers of pages to printed output, the Vareo/InfiniTrim production line can be connected with smart conveyors so that:

1) Multiple Vareo binders can be attached to a single InfiniTrim and,

2) Trimmed books can be diverted down different conveyor paths to segregate workflow for hardcover or softcover or different formats, all the while retaining the exact job sequence for subsequent processing with other personalized components.

The bottom line benefit? Book manufacturers can add incremental volume to their production platform no matter how small the run or variable the format. Contact your local Muller Martini representative today for more information about these profit-generating technologies.