For many years, the gold standard for high-quality hardcover production was a hand-crafted smythe sewn book where groups of folded pages, or signatures, are stitched together to create a book block. The use of colored threads in the headband was both a decorative feature and a signal of high quality and robust durability. As early as the 1990’s, however, the feasibility of smythe sewing was challenged. Improved adhesives were becoming an effective book binding alternative, and trends toward shorter runs were laying the groundwork for faster turnarounds and higher production speeds.

Book production is once again thriving due to highly automated solutions.

Despite continued competition from electronic delivery methods, publishers continue to order paper books in record volumes. But, ironically, digital book manufacturing has brought us back to how book-making originated: producing one book for one specific end-user. However, for today’s book binding to be profitable, printers and binderies must have the ability to produce single copies faster, better, and cheaper than ever before.

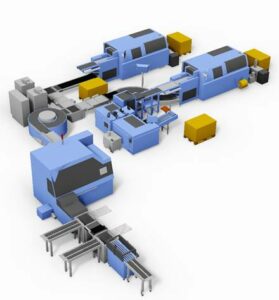

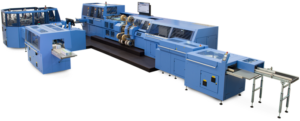

To meet these new market demands. Muller Martini offers a comprehensive, flexible suite of digital book production tools that deliver ultra-efficient production of quality hardcover books of one, specifically:

Ventura Digital MC for folding, collating, and sewing digital sheets into text blocks of arbitrary thickness and number.

Ventura Digital MC for folding, collating, and sewing digital sheets into text blocks of arbitrary thickness and number. Vareo Perfect Binder with in-line end-sheet tipper and crash feeder which automates the entire bookblock process.

Vareo Perfect Binder with in-line end-sheet tipper and crash feeder which automates the entire bookblock process. Diamant MC for casing in every type of hardcover book, from thick to thin, large or small, many to book of one.

Diamant MC for casing in every type of hardcover book, from thick to thin, large or small, many to book of one.Changing dynamics demand new bookbinding methods.

Today’s hardcover bookbinding equipment provides every print facility an opportunity to offer innovative, on-demand bookbinding solutions that provide clear competitive advantages and grow your business. Perhaps it’s time you considered investing in these highly automated solutions that can dramatically lessen labor and speed workflow—while delivering the same traditional quality that readers expect.

To learn more, contact your Regional Sales Manager. Or look for my future blogs which offer further details about Muller Martini’s suite of digital book production tools.

1 comment for “Today’s Digital Hardcover Mandate: Modern methods. Old-world quality.”