In his blog of April 13, 2021, backed up with a detailed whitepaper, my colleague Markus Bracher, Head of Solutions Engineering at Muller Martini, showed you how to turn your analog print shop into a digital one. With a four-part blog series, I would like to introduce you to four Muller Martini customers of different sizes, product and production requirements who, together with Muller Martini, have found a solution for their networked systems and production cells and, with four steps, have become prime examples of a Smart Factory. They impressively demonstrate that the Smart Factory is already a reality today.

A production environment that organizes itself? Bookbinderies whose production processes are completely automated – from transport to in-plant logistics and material flow? A digital book production system that produces 100 individualized book-of-ones almost as quickly as 100 copies of a single title? And without human intervention in the production process?

The magic word to answer these questions, which until a good decade ago seemed almost utopian, is Smart Factory. In the wake of Industry 4.0, the Smart Factory is now a reality in the graphic arts industry. This is because only the networking of embedded production systems and dynamic business processes makes it possible to manufacture products profitably, even with individual customer requirements.

With its development strategy Finishing 4.0, which is based on Industry 4.0, Muller Martini is a leader in the implementation of networked production processes. The biggest drivers of this are new business models. Keywords here are Variable Data Printing (VDP), personalized print products, photo books, Web2Print and Print-on-Demand.

The customer

Muller Martini’s typical Smart Factory customer presented in this blog is a company that has large-scale facilities for (partially individualized) and fully networked volume production. It has set itself the goal of fully integrating the different types of production.

Step 1: understanding digitization

Our customer’s challenge was to seamlessly connect the company’s systems, which had grown historically over the years (an elaborate tool landscape with its own IT systems and HP digital printing system), with Muller Martini’s Connex workflow system.

Step 2: clarify company requirements

On the one hand, the production forms in this company are different – from softcover to hardcover to saddle stitching. On the other hand, the product range is very broad – from individualized teaching materials to VDP insurance policies. And the products come from both digital and offset printing. It is correspondingly demanding to coordinate the various finishing systems with their different peripheral systems.

Step 3: achieve process competence

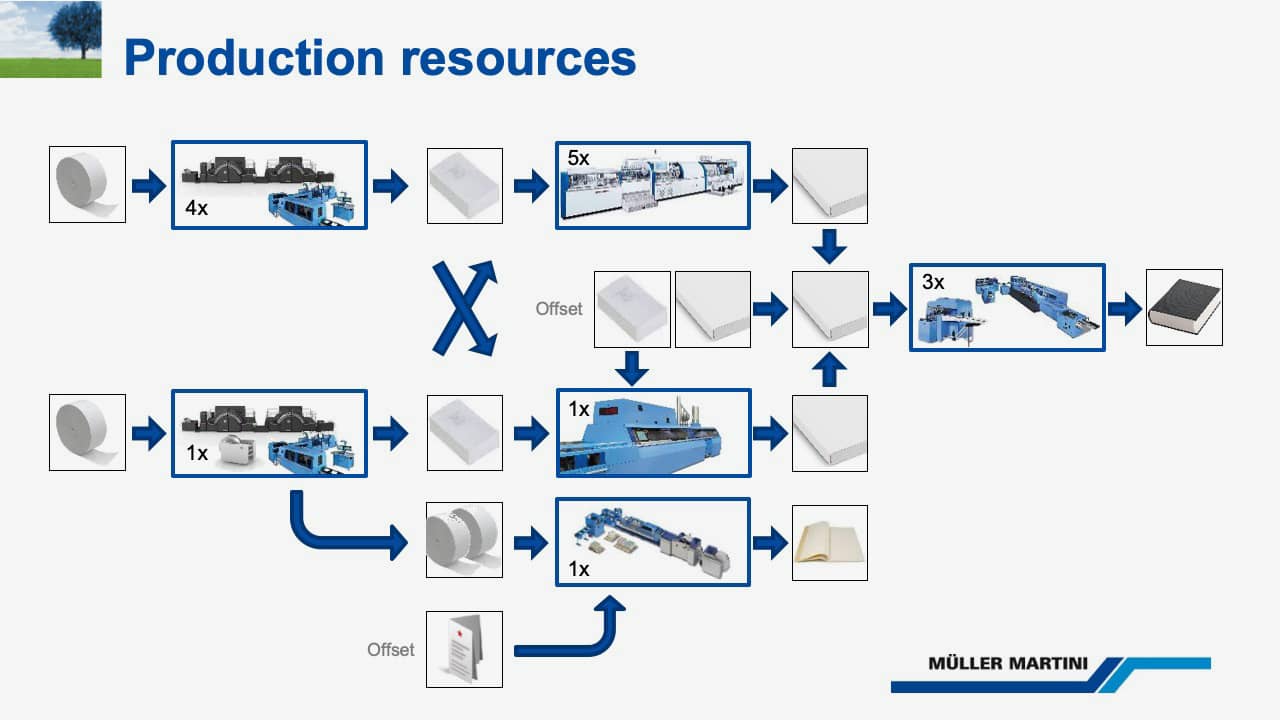

When four SigmaLine digital book block systems “feed” five KM 200 perfect binders and three Diamant MC book lines, and one SigmaLine “feeds” an Alegro perfect binder and a Presto II Digital saddle stitcher, and all the machines are also networked via Connex, then this nearline solution – inline is “only” the HP digital press/SigmaLine link – requires a high level of process expertise.

This extremely high level of automation brings the customer great advantages in several respects. Firstly, it enables a massive reduction in manual intervention in all production steps; secondly, automatic, seamless production tracking for each individual product; and thirdly, there is only one contact for the entire production chain.

Step 4: shaping digital transformation

Thanks to the integration of all production cells via Connex, the entire workflow at this customer can be controlled using a digital order bag. This enables end-to-end integration from prepress to the finished product. For more than 6 million PDF files per year, there is fully automated imposition (including imposition on a 40-inch roll for 2 x 20-inch production) and fully automated production management.

The top 5 benefits of this customer example and your advantages at a glance

- Benefit 1: The complex in-house systems can be seamlessly connected to the Connex workflow system from Muller Martini. – Your advantage: You have a lean and cost-efficient integration thanks to the use of proven and well-known IT interfaces.

- Benefit 2: Connex networks no fewer than 14 Muller Martini systems with five SigmaLines, five KM 200 perfect binders, three Diamant MC booklines and one Presto II Digital saddle stitcher, ensuring a seamless production process that requires minimal manual intervention – in line with Muller Martini’s Finishing 4.0 philosophy. – Your advantage: You have a uniform interface for integrating a wide variety of machines. This minimizes your maintenance effort for IT operations, even for software updates on the machines.

- Benefit 3: Thanks to the integration of all production cells via Connex, the entire workflow is controlled by means of a digital order bag. – Your advantage: Redundant data entries are eliminated, and thus there are also fewer sources of error. The order run sheets become simpler and easier to understand. They are only used for identification purposes and no longer contain any order data.

- Benefit 4: There is an automatic production tracking for each individual product. – Your advantage: You have an up-to-date, accurate and detailed overview of production progress at all times, even with book-of-one. The completeness of your customer orders is continuously monitored and ensured.

- Benefit 5: There is only one contact person for the entire production chain. – Your advantage: From spare parts to data integration – Muller Martini is your strong partner for all your needs.

A valuable white paper to download

If you would like more in-depth information about the digital transformation and Muller Martini’s ideas on the Smart Factory, I recommend that you read our detailed whitepaper on this topic. You can conveniently download it here.

In the second installment of our blog series on August 17, get to know a company that has an extensively networked and partially individualized short-run production with cloud connection and has set itself the goal of efficient production without machine stoppages.