Long- and short-run saddle stitching productions have always posed some finishing challenges. You needed dedicated lines for long-run offset productions and separate lines for feeding digitally printed products. But when your machines remained idle as volumes of one or the other did not meet full capacity, your investments remained idle too.

Now a single line can handle both your offset and digital production needs

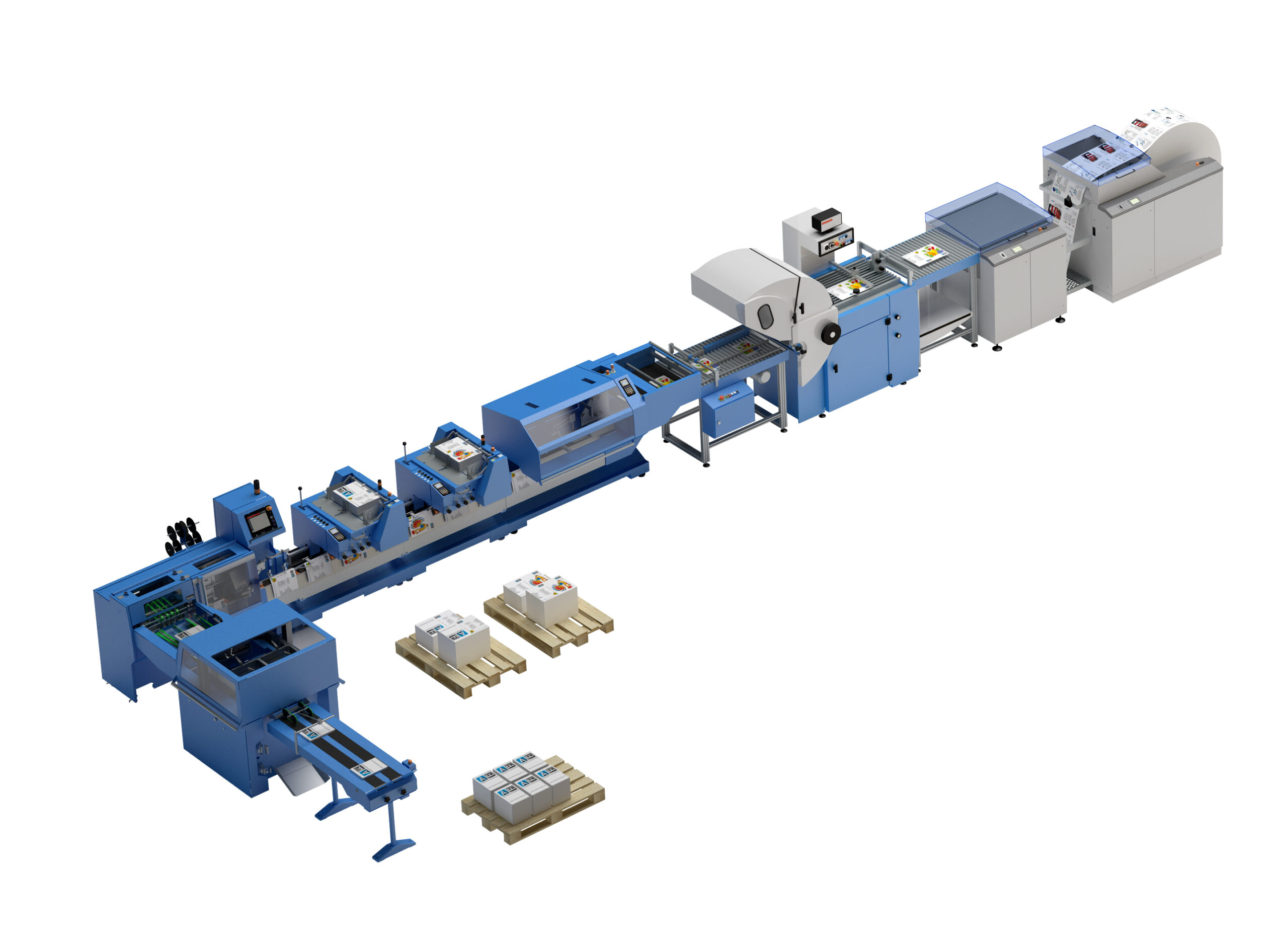

With speeds ranging from 9K to 14K copies per hour, Müller Martini’s hybrid saddle stitching solutions can handle both production types in a single line.

- Offset production utilizes Müller Martini’s latest proven saddle stitching components for feeding offset printed signatures with enhanced quality controls and accessories.

- Digital production utilizes roll- or cut-sheet feeding devices fully integrated into Müller Martini’s saddle stitching lines. It offers cut sheet processing with a wide range of sheet sizes possible, with or without inline folding. In addition, roll feeding processing capabilities with a wide range of roll widths are possible as well as dynamic variable cutting and folding for all paginations. For those who have both cut-sheet production and roll feeding production, you can now use the same production line to process these types of digitally printed products.

- Müller Martini “hybrid” digital saddle stitching lines offers a single production line to run offset or digital production. Combination of feeding digitally printed products from roll or cut sheet and adding offset content fed from traditional offset feeder. The thickness variability book to book is the complete thickness range of saddle stitching line books that can be produced in any sequence regardless of thickness. It has the flexibility to separate lines for offset production and use digital roll or cut sheet feeding devices for other types of work, such as book block production, folding jobs, and more. The barcode-driven workflow tracks every sheet and every book produced for content validation and content matching for one-off personalization books. Connex workflow solutions provide detailed information to the customer on all books produced or rejected for reprint; complete validation of products produced.

And that’s the long and short of it. But don’t take my word for it. Join Muller Martini at Print United 2022! The most dynamic and comprehensive printing event in the world. Oct 19th -21st at the Las Vegas Convention Center 3150 Paradise Road, Booth N343!

In the meantime, I’m always happy to answer any questions you may have regarding our saddle stitching equipment.